Simplify PCB Power Relays: How Does a PCB Relay Work?

Introduction to PCB Power Relays

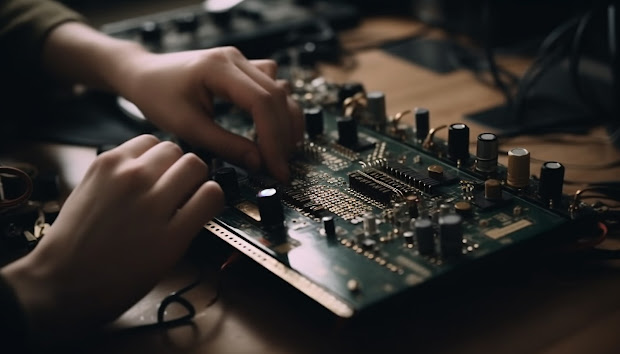

As an electronics enthusiast, you may have

come across the term “PCB

power relay" in your projects or research. But what exactly is

a PCB power relay, and how does it work? In this article, we will delve into

the world of PCB power relays, exploring their components, design, and most

importantly, their function and purpose.

What is a PCB Power Relay?

A PCB power relay, also known as a printed

circuit board power relay, is an electromechanical device that allows the

control of high-power electrical circuits through low-power signals. It is an

essential component in many electronic devices and systems, providing an

interface between the control circuit and the load circuit.

The Function and Purpose of a PCB Power Relay

The main function of a PCB power relay is

to control the flow of electrical current in a circuit. When a low-power

signal, such as a voltage or current, is applied to the relay's coil, it

generates a magnetic field that attracts or releases a set of contacts. These

contacts, in turn, open or close the circuit, allowing or interrupting the flow

of electricity to the load.

The purpose of a PCB power relay varies

depending on the application. In some cases, it is used for power switching,

where it controls the flow of electricity to devices such as motors, lamps, or

heaters. In others, it acts as a protective device, safeguarding the circuit

from overloads or short circuits. Power

relays are also commonly employed in automation systems, industrial control

panels, and telecommunications equipment.

Components and Design of a PCB Power Relay

To understand how a PCB power relay works,

it is crucial to familiarize yourself with its components and design. The main

elements of a typical PCB power relay include the coil, contacts, and the

magnetic system.

The Coil

The coil is the primary component of a PCB

power relay responsible for generating the magnetic field. It is usually made

of copper wire wound around a bobbin or a magnetic core. The number of turns

and the gauge of the wire determine the coil's resistance and the amount of

current required to energize the relay.

The Contacts

The contacts of a PCB power relay are the

crucial link between the control circuit and the load circuit. They are made of

conductive materials, such as silver or gold-plated alloys, to ensure efficient

electrical conduction and minimize contact resistance. PCB power relays can

have various contact configurations, including single-pole, single-throw

(SPST), single-pole, double-throw (SPDT), and double-pole, double-throw (DPDT).

The Magnetic System

The magnetic system of a PCB power relay

consists of a ferromagnetic core and an armature. When the coil is energized,

the magnetic field created by the coil attracts the armature, which is

mechanically linked to the contacts. This attraction causes the contacts to

move, either opening or closing the circuit, depending on the relay's design

and specifications.

How Does a PCB Power Relay Work?

Now that we have a basic understanding of

the components, let's explore how a PCB power relay works in practice. The

operation of a PCB power relay can be divided into three main stages: the

resting state, the activation state, and the switched state.

Resting State

In the resting state, the relay is not

energized, and the contacts are in their default position. Depending on the

relay's design, this default position can be either open or closed. For

example, in a normally open (NO) relay, the contacts are open in the resting

state, while in a normally closed (NC) relay, the contacts are closed.

Activation State

When a voltage or current is applied to the

coil, it creates a magnetic field that attracts the armature. This attraction

causes the armature to move, which, in turn, moves the contacts. If the relay

is normally open, the contacts will close, completing the circuit and allowing

the flow of current to the load. Conversely, if the relay is normally closed,

the contacts will open, interrupting the circuit.

Switched State

Once the coil is de-energized, the magnetic

field dissipates, and the armature returns to its original position due to

factors such as spring tension. As a result, the contacts also return to their

default position, either open or closed, depending on the design of the relay.

This completes the switching action, and the relay is ready for the next cycle.

Advantages and Applications of PCB Power Relays

PCB power relays offer several advantages

that make them a popular choice in various applications. One of the key

advantages is their ability to handle high-power loads while being controlled

by low-power signals. This feature allows for efficient and reliable control of

electrical circuits, making PCB power relays indispensable in industries such

as manufacturing, automotive, and telecommunications.

Another advantage of PCB power relays is

their compact size. Since they are designed to be mounted directly onto printed

circuit boards, they occupy minimal space, making them suitable for

applications where size constraints are a concern. Additionally, they are

relatively easy to install and replace, reducing downtime and maintenance costs

in case of failure.

The applications of PCB power relays are

wide-ranging. They are commonly used in automotive systems, such as power

windows, central locking, and fuel pumps. In industrial settings, they play a

vital role in controlling motors, pumps, and solenoids. In the field of

telecommunications, PCB power relays are utilized in devices like switches,

routers, and modems. These relays also find their place in renewable energy

systems, home appliances, and medical equipment.

Understanding Different Types of PCB Power Relays

PCB power relays come in a variety of

types, each suitable for specific applications and requirements. The most

common types include general-purpose

relays, latching relays, solid-state relays, and automotive relays.

General-purpose relays are versatile and

can be used in a wide range of applications. They are available in different

configurations, contact ratings, and coil voltages, making them suitable for

both low-power and high-power switching.

Latching

relays, also known as bistable relays, have the ability to maintain their

contact position even after the coil is de-energized. They are commonly used in

applications where power consumption and heat generation need to be minimized.

Solid-state relays (SSRs) differ from

traditional electromechanical relays as they use semiconductor devices and

optocouplers to control the switching action. SSRs offer advantages such as

silent operation, long lifespan, and fast switching speeds. They are often used

in applications where high switching frequency and low power consumption are

critical.

Automotive

relays are specifically designed to withstand the harsh conditions and high

electrical demands of automotive systems. They are frequently used in vehicle

lighting, wiper control, and ignition systems.

Choosing the Right PCB Power Relay for Your Application

Selecting the right PCB power relay for

your application is crucial to ensure optimal performance and reliability.

Several factors should be considered, including contact ratings, coil voltage,

switching speed, and environmental conditions.

Firstly, determine the required contact

rating, which specifies the maximum current and voltage that the relay can

handle. This rating should be compatible with the load circuit's electrical

characteristics to prevent damage or failure.

The coil voltage is also an essential

parameter to consider. Ensure that the relay's coil voltage matches the voltage

available in your control circuit. Operating the relay with a higher or lower coil

voltage than specified can lead to improper functioning or complete failure.

The switching speed of a PCB power relay is

another critical factor, especially in applications where fast response times

are required. Consider the relay's datasheet or technical specifications to

determine its switching speed and choose accordingly.

Lastly, take into account the environmental

conditions in which the relay will operate. Factors such as temperature,

humidity, vibration, and shock can significantly impact the relay's performance

and lifespan. Choose a relay that is specifically designed to withstand the

environmental conditions of your application.

Leading Manufacturers of PCB Power Relays

When it comes to choosing a reliable PCB

power relay, it is essential to consider reputable manufacturers known for

their quality and performance. Some of the leading manufacturers in the

industry include Omron, TE

Connectivity, Panasonic,

Siemens, and Schneider Electric.

Omron, for instance, is a renowned

manufacturer offering a wide range of PCB power relays suitable for various

applications. Their relays are known for their high-quality construction,

excellent performance, and long lifespan.

TE Connectivity is another trusted name in

the field of PCB power relays. They provide a comprehensive selection of

relays, catering to different industries and requirements. Their relays are

known for their durability, versatility, and advanced features.

Other notable manufacturers like Panasonic,

Siemens, and Schneider Electric also offer a diverse range of high-quality PCB

power relays, ensuring reliability and performance in demanding applications.

Conclusion: The Importance of PCB Power Relays in

Electronics

In conclusion, PCB power relays play a

vital role in the world of electronics, enabling the control of high-power

circuits through low-power signals. Understanding their components, design, and

operation is essential for anyone working with electronic devices or systems.

By demystifying PCB power relays, we have

gained insight into their function, purpose, advantages, and applications. We

have explored different types of relays and discussed the factors to consider

when choosing the right one for your application. Additionally, we have

highlighted leading manufacturers known for their quality and reliability.

Next time you encounter a PCB power relay

in your projects, remember its significance in providing efficient and reliable

control of electrical circuits. Whether you're working on an industrial

automation system, a telecommunications device, or a home appliance, PCB power

relays are the unsung heroes ensuring seamless operation and protection of your

electronics.

Comments

Post a Comment